We are a group company of SCREEN Holdings Co., Ltd.

Products

MED64: Record important extracellular signals that can be hidden by other systems!

The MED64 Systems are user-friendly microelectrode array (MEA) system for in vitro extracellular electrophysiology. Acute or cultured biological preparations are placed or grown directly on a grid of planar microelectrodes, which serve dual purpose: record of field potential at each electrode and deliver stimulation via any electrode.

The MED64 features with the industry's most sensitive MEA system due to its lowest-impedance electrodes. Started by Panasonic, the MED64 has been on market for 20 years with hundreds of users and publications worldwide.

Advantages

Reveal important extracellular signals that can be hidden by other systems!

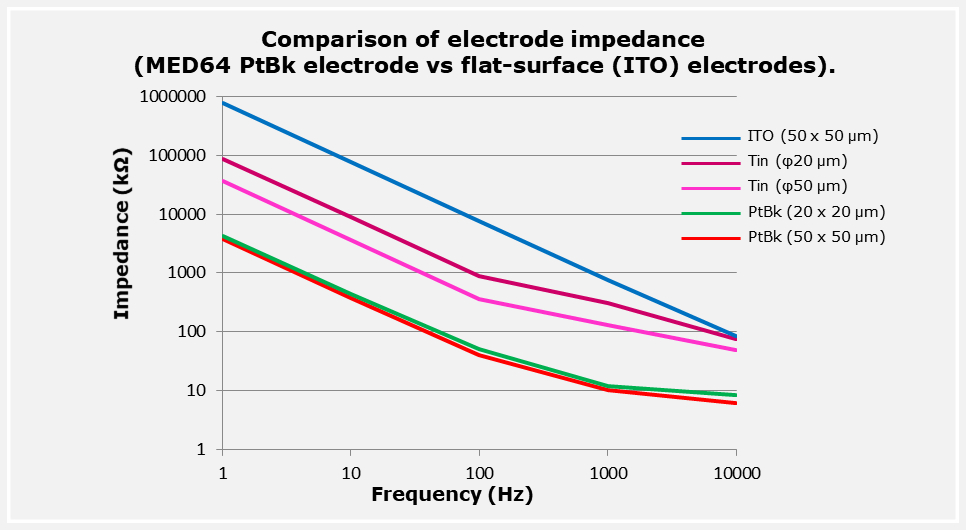

The MED64 features with the industry’s lowest-impedance planar microelectrodes (10 kohm at 1 kHz), that afford several unique benefits:

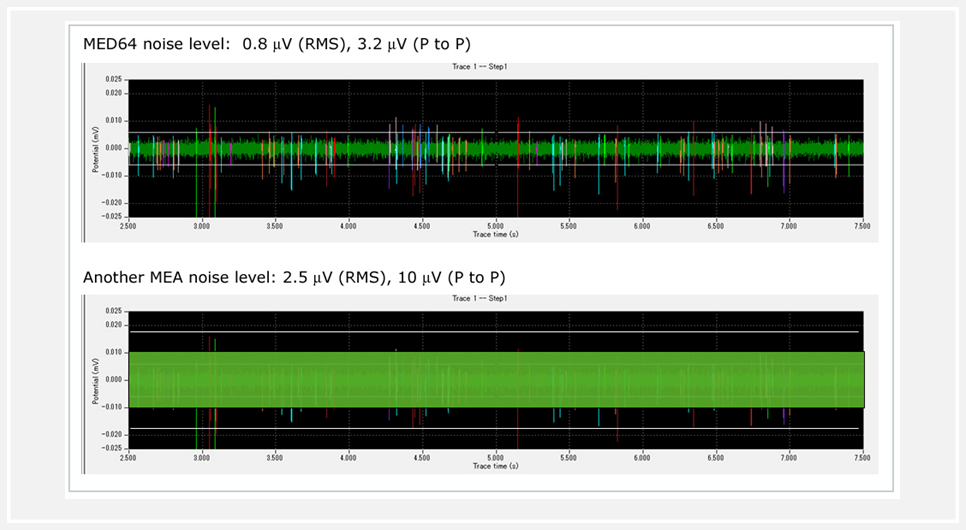

The most sensitive (The best signal-to-noise ratio)

Electrode impedance is a major factor in determining an electrophysiological acquisition system's baseline noise level. Lower electrode impedance results in lower baseline noise level. When using MEAs, having a low baseline noise is the only method to achieve a good signal-to-noise ratio because electrodes do not penetrate into biological samples.

Thanks to the industry's lowest-impedance electrodes, the MED64 can provide the lowest baseline noise level which can reveal important signals that may be hidden by other systems.

Recording inside of a humidified incubator

A general rule for electrophysiology system is “The head amplifier need to be placed close to electrodes”. However, MED64’s low-impedance electrodes do not even require this configuration. The MED Connector (holding the MEA) is connected to the amplifier via a 2 meter long cable, that does not generate signal attenuation.

Excellent capabilities for stimulation

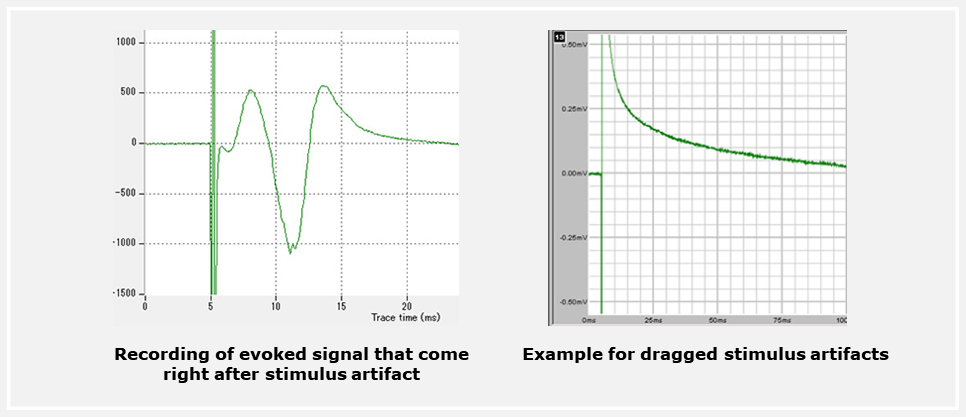

Stimulation using the planar microelectrode is more challenging than recording. One of the reasons is stimulated electrodes need some time to discharge. This phenomenon appears as “dragging of stimulus artifacts”, that interferes signals coming right after the stimulation.

The MED64’s lowest-impedance electrodes make this discharge instantly, where the stimulus artifacts returns to 0 within 0.5 msec. Evoked signals can be clearly measured immediately after stimulation. MED64’s excellent stimulation capabilities are validated by hundreds of publications.

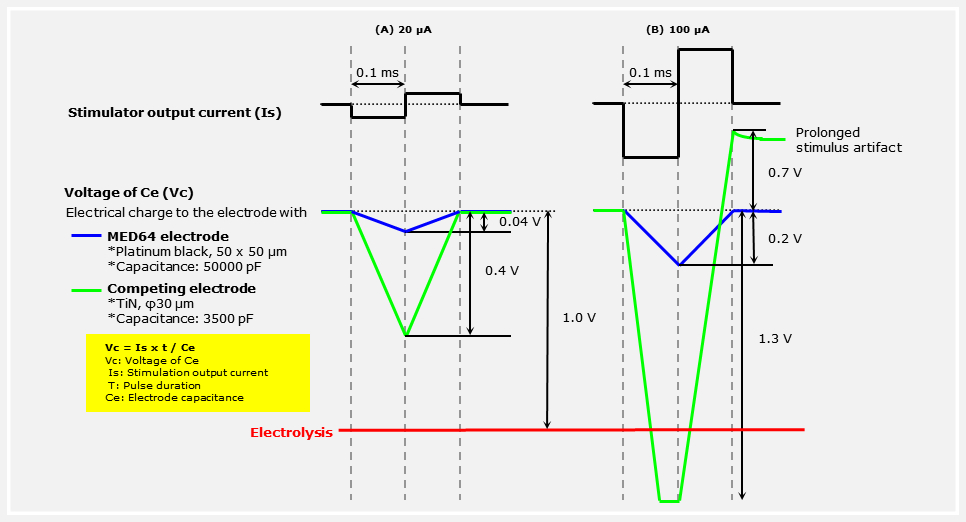

A rate limiter for stimulating with MEAs is that voltage charged to planar electrodes must not go beyond 1V to avoid electrolysis. This could hamper the amplitude of the current that can be delivered through an MEA.

The MED64’s planar microelectrode has much higher capacitance (22,000 pF for 50 μm electrode) relative to other commercially available MEA, enabling large current-driven stimulation (up to 200 μA) to all electrodes of the MED64.

Differences in behavior in response to stimulation for electrodes of different material composition

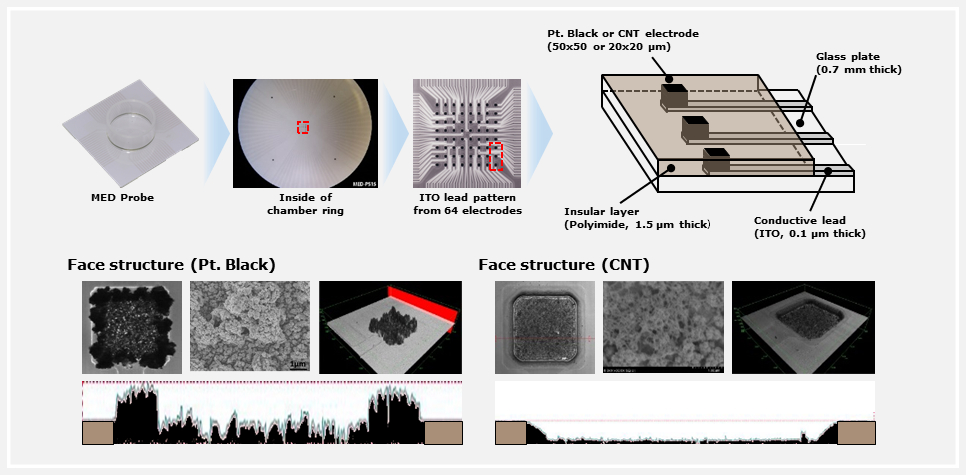

What is the reason for the low-impedance?

Making planar microelectrodes for MEA is difficult. MEA electrodes need to have large surface area to achieve low-impedance (Electrode impedance is inversely proposed to its surface area).

This dilemma can be solved by making electrode surface rough on the nano level. The planar microelectrode of the MED Probe is coated with platinum black using a unique technology that Panasonic/Alpha MED established. This manufacturing method dramatically increases the electrode surface area 100-200x larger and its impedance decreases accordingly.